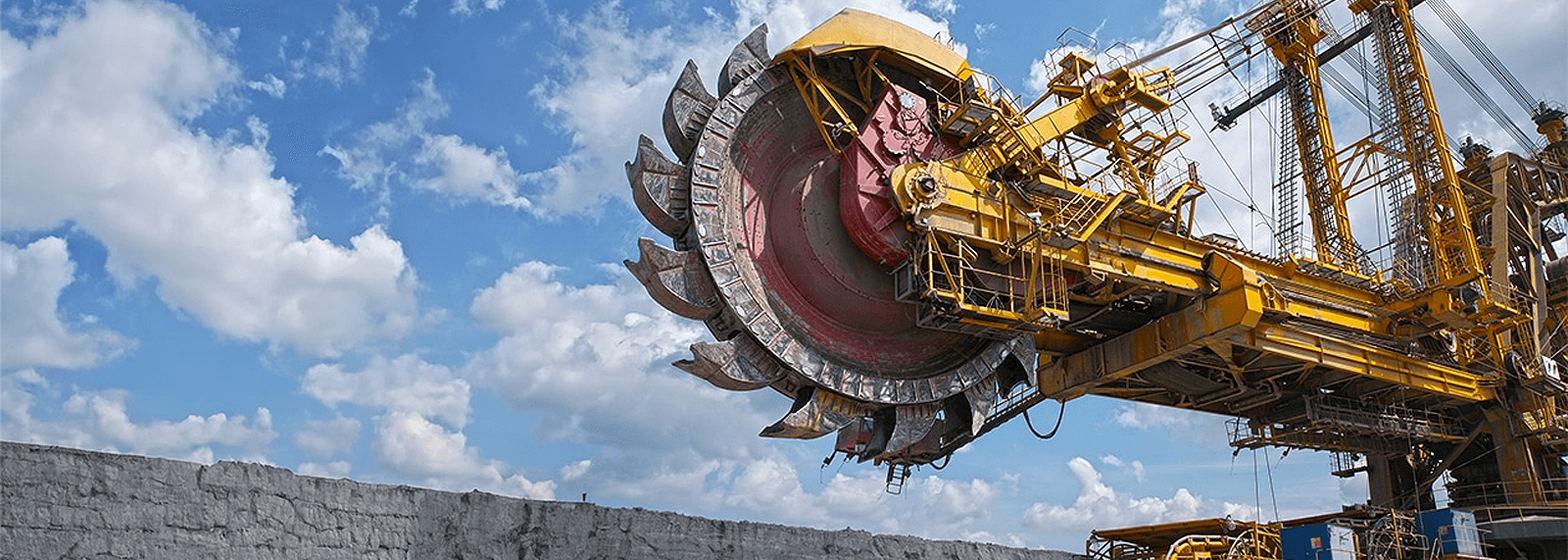

At the heart of mining and hydraulic fracturing, two of the most demanding industries on the planet, lies an often underestimated but absolutely critical component: industrial grease. Far from being a simple lubricant, grease is a protective shield, a productivity enabler, and a pillar of safety in environments where machinery faces extreme conditions, from overwhelming pressure to constant exposure to corrosive elements.

A job under pressure: more than just lubrication

Mining and fracking operations subject equipment to unbearable pressure and friction. This is where a high-quality grease proves its value. Unlike oils that flow, greases stay in place, providing a constant barrier that prevents metal-to-metal contact. This not only reduces wear on expensive components like bearings and gears, but also minimizes the risk of catastrophic failure.

- Protection against contaminants: Dust, dirt, water, and sludge are the norm in these environments. A well-formulated grease seals equipment cavities, preventing these abrasive contaminants from penetrating and causing irreparable damage.

- Extreme Temperature Resistance: Heavy machinery, such as drills and haul trucks, generates intense heat. Climates can vary dramatically. Lone Star industrial greases are designed to maintain consistency and effectiveness across extreme temperature ranges, ensuring optimal performance regardless of the conditions.

- Reduced Costs and Increased Productivity: By extending the life of machinery and reducing the need for unscheduled maintenance, high-performance greases are a smart investment. Less downtime means greater operational efficiency and, ultimately, increased profitability for your business.

The Lone Star Experience in Action

At Lone Star, we understand that the right grease can make the difference between smooth operations and costly downtime. Our specialized formulations not only meet but exceed the unique challenges of mining and fracking. That’s why we partner with you to offer more than just a product: we provide expert technical support, reliable logistics service, and the peace of mind that comes with knowing your equipment is protected by the best.

Trust the quality and expertise that only a family-owned company like ours can offer. Because when it comes to your most critical operations, there’s no room for compromise.

Frequently Asked Questions (FAQ)

Why not simply use oil instead of grease?

Although oils are excellent lubricants, greases are superior for mining and fracking applications because they have a semi-solid consistency. This allows them to adhere to components and provide consistent lubrication, especially in areas where oil would otherwise leak. They also act as a protective seal against dust, water, and other contaminants.

How often should grease be applied?

The frequency of re-greasing depends on several factors, such as the type of equipment, operating conditions (temperature, load), and the type of grease used. Our solutions are long-lasting, and with the support of our technicians, we can help create a lubrication program optimized for your specific needs, which will reduce maintenance and increase the lifespan of your machinery.

Can I mix different types of grease?

This is not recommended. Mixing greases with different formulations can cause chemical incompatibility, which can negatively affect their performance and reduce their effectiveness. It’s always best to consult an expert to determine the appropriate grease and the correct procedure for your equipment.

832 858 6909

832 858 6909 contact@lonestargl.com

contact@lonestargl.com